en you hear the words, warehouse racking , two things usually come to mind; pallet racking and cantilever racking . So whilst racking style should your business use, is it all down to personal preference, or are there clear advantages of different styles in different situations and circumstances?

Warehouse Racking – Pallet Or Cantilever?

Warehouse racking storage systems can be used to store a wide variety of different things ranging from food items, to construction materials, or even tyres for cars and motorcycles. The items that you are storing in your warehouse will lead to different methods of storage being preferable, so when should you use pallet racking and when should you use cantilever racking?

When To Use Cantilever Racking

When To Use Cantilever Racking

The word cantilever means 'a beam which is anchored at only one end'. In a cantilever rack system, bases are anchored to the floor ready to connect to the unit's uprights, providing stabilisation for the racking system. The cantilever storage system is the optimum way to store long and heavy products. Simply put, a cantilever rack system allows businesses to store items that cannot be easily stored on a pallet racking system. In pallet racking, the vertical obstructions restrict the length of what can be stored in a pallet racking system. However, the strong uprights and cantilever arms allow for longer and heavier items.

This method of storage is often found in timber yards and builder's merchants. Some of the materials that can be stored sheet materials, tubes, bars, and rods. Cantilever systems also have the advantage of being relatively easy to install and configure with the possibility for additional arms being added; providing businesses with the flexibility to store a range of objects in all shapes and sizes.

When To Use Pallet Racking

Whilst solutions such as cantilever racking have many advantages, it is important to remember that there are also many disadvantages; as such in some situations it will be vastly superior to use a pallet racking system.

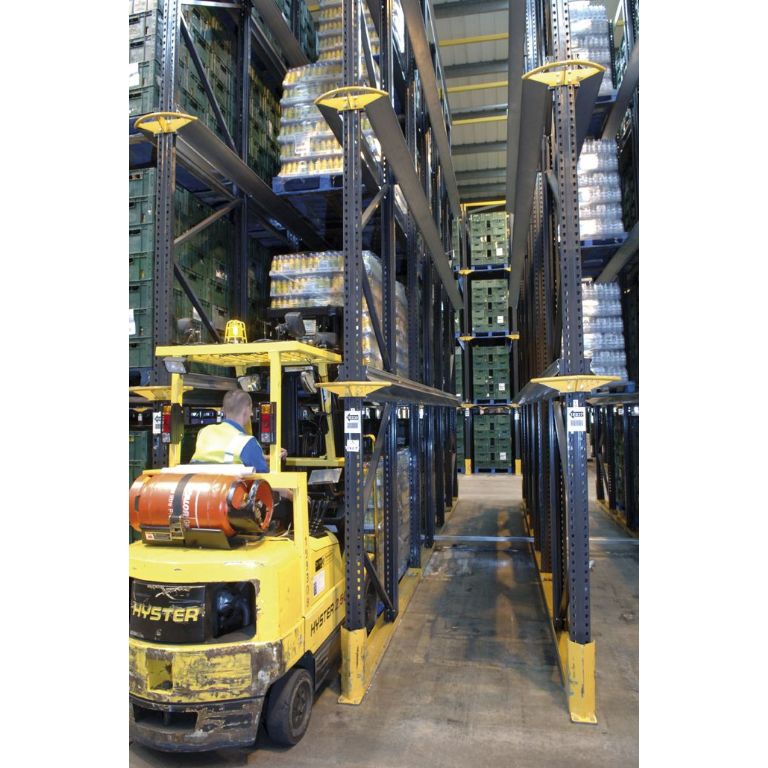

For example, cantilever systems can provide issues with forklifts, however wide aisle pallet racking doesn't have this issue. In a wide aisle solution, most forklift trucks can operate in aisles up to 4m wide, picking staff have 100% immediate and unrestricted access to each pallet, no specialised materials or handling equipment is needed, and stock check and control is very easy.

What Solution Is Right For You?

If you are unsure what type of racking system or combination of systems is required for your warehouse or storage area, do not worry. The P&D Projects team will be happy to help you select the right system. This will depend on the following considerations:

- The type of goods and stock keeping units (SKUs) you need to store.

- The size and weight of your pallets.

- The amount of floor space available for the racking installation.

- The speed of throughput and pick rate.

- The type of handling equipment used.

What About Other Storage Options?

Whilst a diverse variety of different products and items can be stored in pallet or cantilever racking style storage solutions, some products have more specific storage requirements which request a tailor made solution. One such example is tyres.

Tyre racking is different when compared to cantilever or pallet systems. Sometimes also called automotive racking, this method of storage allows for tyres to be stored vertically. If the racking system is free-standing, you can store tyres up to three levels high, or they can be bolted to the floor to provide four storage levels.

Here at P&D Tyre racking solutions are a particular niche of ours and we deal with many top names in the motor industry on a regular business. Several of which include some of the UK's leading tyre wholesalers; with top names such as, Audi, Mercedes-Benz, and VW.

Warehouse Racking Solutions From P&D Projects

If your warehouse is suffering from poor workplace efficiency, perhaps you're not currently utilising the best suited system and as such your warehouse could benefit from a different racking system? Perhaps even a combination of systems is required?

However, if you're unsure which system would be best suited to your needs, worry not because our warehouse storage specialists will be happy to provide assistance. Our team offer a free consultation and CAD presentation; additionally we are happy to arrange for a site survey to discuss your requirements.

Interested? Get In Touch With Our Team Today To Make An Enquiry

If you have any questions or if you would like to request a quote, please don't hesitate to get in touch with a member of staff. You can contact our team by telephone or by email using the information below.

- Contact Our Team By Telephone.

If you would like to speak to a member of our team via the telephone, please call us on 01344 623100.

- Contact Our Team By Email.

If you would prefer to make your enquiry using the internet, you can send any questions you have regarding our services to us by email. Our email address is enquiries@panddprojects.co.uk .

- Request A Call Back.

If you would like to request a call back, please click the 'Quick Call Back' button on the side of your browser.